Battery Separator

Flat PP separator series

- Product ID:Battery Separator

- QQ:

- Phone: 008618014912498

- Tel: 008618014912498

- Email: hengshinewmaterial@outlook.com

- Time: 2024-03-14 16:41:53

- FEEDBACK

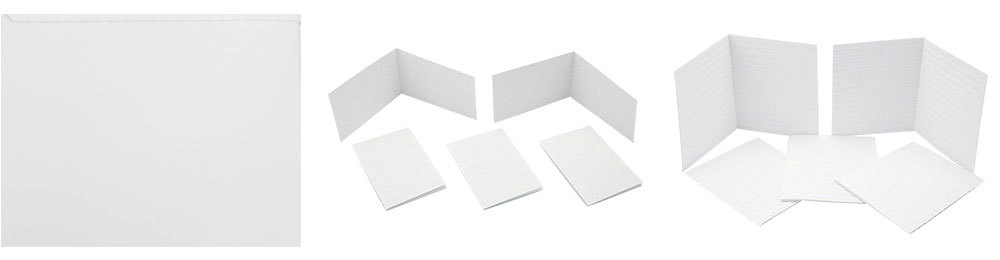

The melt blown polypropylene battery separator (PP separator) is suitable for low-end and inexpensive automotive and motorcycle batteries; PP separators come in various forms and can be processed into flat and ribbed separators of various sizes and specifications.

In order to solve the stiffness defects of PP separators, ribbed PP separators were introduced to improve their electrical performance and stiffness. And in order to protect the anode plate in lead-acid batteries, prevent lead powder from falling off and earthquake resistance, bag type PP separators have been introduced.

TECHNICAL DATA

Item | Unit | Parameters | ||

Back web | mm | ≤0.50 | 0.50~0.80 | >0.80 |

Total thickness | mm | (0.80~1.30)±0.05 | ||

Electrical resistance | Ω.dm2 | ≤0.0010 | ≤0.0015 | ≤0.0020 |

CMD stretch rate | % | ≥300 | ||

Porosity | % | ≤65 | ||

Maximum pore size | μm | ≤36 | ||

Shrinkage | % | ≤1.0 | ||

Wet ability | s | ≤5.0 | ||

Weight loss in acid | % | ≤4.0 | ||

Moisture | % | ≤4.0 | ||

Iron content | % | ≤0.010 | ||

Chlorine content | % | ≤0.030 | ||

Reduced potassium permanganate substances | Ml/g | ≤15 | ||

Foaminess | / | Bubbles (foam) cannot completely cover the surface of sulfuric acid solution | ||

lamination | / | No layering gap | ||

Application of PP separator in starter batteries and its existing problems

The biggest problem with PP separators is the lack of antioxidant properties:

① The surface area of ultrafine fibers in raw materials is larger, making them more susceptible to thermal aging;

② High temperature process leads to the loss of antioxidants;

③ In the water washing process, it can also promote the aging of the separator.

CATEGORIES

LATEST NEWS

- BASF Launches Polyurethane Composite Material Battery Pack Shell Solution

- What are the physicochemical indicators and types of separator materials for lithium-ion batteries?

- What is a lithium battery pack? What are the components and advantages of a lithium battery pack?

- What requirements should lithium-ion battery electrolytes meet?

- What are the materials for lithium-ion batteries?

CONTACT US

QQ:

Phone: 008618014912498

Tel: 008618014912498

Email:

Add: Jiangdong Street, Yiwu City, Zhejiang,China