Battery Separator

Automotive PE separator series

- Product ID:Battery Separator

- QQ:

- Phone: 008618014912498

- Tel: 008618014912498

- Email: hengshinewmaterial@outlook.com

- Time: 2024-03-14 16:18:27

- FEEDBACK

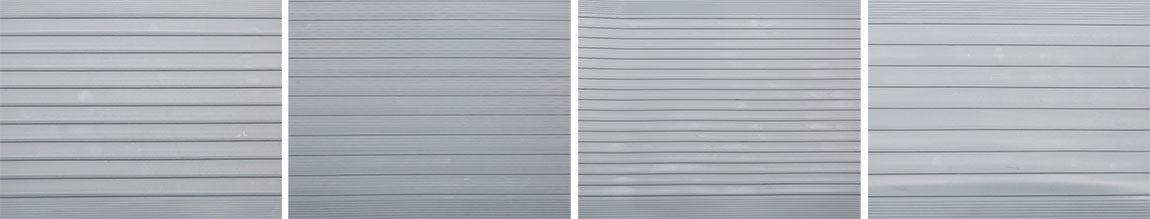

This model of separator has double-sided ribs, with thick ribs on the front and thin ribs on the front. The spacing between the ribs is reduced compared to the first conventional type, and the corresponding number of ribs increases. The increase in the number of ribs provides more sufficient space for the electrode plate and space for the presence of free state electrolytes, as well as pressure for the electrode to maintain contact with the separator; Meanwhile, an increase in the number of bars can to some extent prevent the lead powder from falling off the electrode plate and causing short circuits at the bottom of the battery. However, compared to the previous single-sided reinforcement, the relative resistance of this type of separator will be slightly higher. In addition, after multiple tests and assembly by battery manufacturers, it was found that this multi rib separator is more conducive to the packaging of automatic packaging machines, greatly improving production efficiency, reducing the scrap rate during the electrode packaging process, and saving costs for manufacturers to a certain extent.

TECHNICAL DATA

ITEM | UNIT | DATA |

Back web | mm | 0.200±0.030 0.250±0.030 |

Back web | mm | (0.80~1.30)±0.05 |

Puncture strength | N | ≥8 |

CMD stretch rate | % | ≥300 |

Electrical resistance | Ω.dm2 | ≤0.0010 Stabdard ≤0.0015 Special |

Porosity | % | ≥55 |

Base oil content | % | ≥8 |

Total oil content | % | 12≤Total≤18 |

Moisture | % | ≤4.0 |

Shrinkage | % | ≤1.0 |

Acid wetting time | s | ≤50 |

Acid wetting loss | % | ≤4.0 |

Fe contents | % | ≤0.010 |

Cl contents | % | ≤0.030 |

Reducing Potassium permanganate | Ml/g | ≤10 |

Oxidative stability transverse elongation after oxidation(CMD) | % | ≥100(48h) |

CATEGORIES

LATEST NEWS

- BASF Launches Polyurethane Composite Material Battery Pack Shell Solution

- What are the physicochemical indicators and types of separator materials for lithium-ion batteries?

- What is a lithium battery pack? What are the components and advantages of a lithium battery pack?

- What requirements should lithium-ion battery electrolytes meet?

- What are the materials for lithium-ion batteries?

CONTACT US

QQ:

Phone: 008618014912498

Tel: 008618014912498

Email:

Add: Jiangdong Street, Yiwu City, Zhejiang,China